Kitting and Assembly Services: Accelerating Deployment Through Pre-Configured Solutions

As telecom and wireless networks scale to meet soaring demand, deployment timelines are shrinking while the availability of skilled field labor continues to tighten. In this high-pressure environment, carriers, contractors and system integrators are turning to kitting and pre-assembly services as both a practical and strategic solution.

These services are no longer just a convenience. They’re transforming how network infrastructure is delivered, installed and managed, offering powerful advantages in speed, accuracy and cost control.

The Case for Pre-Configured Solutions

Traditional network deployments rely heavily on field assembly, with crews juggling components from multiple vendors, improvising on-site and troubleshooting in real time. While flexible, this model introduces risk, resulting in delays, inconsistent quality and rising labor costs.

Kitting and pre-assembly streamline this process by delivering ready-to-deploy solutions tailored to each site or phase. This approach improves operational efficiency in several critical ways:

Reduced on-site labor: Pre-built assemblies minimize the need for technical expertise in the field

Lower error rates: Factory-tested, standardized configurations eliminate guesswork and rework

Improved logistics: Bundled kits simplify inventory management, shipping and staging

Deployment consistency: Repeatable configurations ensure uniform installs across sites and regions

What's Being Pre-Assembled?

Kitting and assembly offerings have evolved from simple cable bundles into comprehensive, turnkey solutions. Today’s pre-configured kits are purpose-built for speed and precision, integrating all required materials, tools and documentation for successful installation.

Common Examples Include:

Pre-terminated fiber assemblies: Factory-tested and certified plug-and-play cables that eliminate on-site splicing

Network cabinets: Racked, powered and pre-configured with routers, switches and power systems for immediate deployment

Pole-mount kits: Fully assembled hardware for small cell radios, remote terminals or power supplies, tailored to specific mounting configurations

Custom cable kits: Site-specific bundles labeled and sorted by phase, reducing confusion and missing parts

At GCG’s Telecom Solutions, each kit includes clear labeling, standardized documentation and detailed installation guides, helping reduce install time and field expertise requirements.

Operational Benefits in the Field

The real value of pre-configured kits becomes clear in the field, where deployment teams face tight windows, unpredictable site conditions and high labor costs.

Tangible Field Advantages:

Faster installs: Especially critical in high-traffic or restricted-access areas like urban rooftops or utility easements

Higher first-time-right rates: Pre-tested kits reduce callbacks and costly rework

Simplified training: Consistent kits lower the learning curve for crews and contractors, improving ramp-up speed

Leaner inventory: Kits enable just-in-time delivery, reducing warehouse overhead and on-site staging complexity

As network complexity increases, particularly in 5G, FTTx and edge deployments, these field efficiencies become crucial for maintaining project momentum and controlling costs.

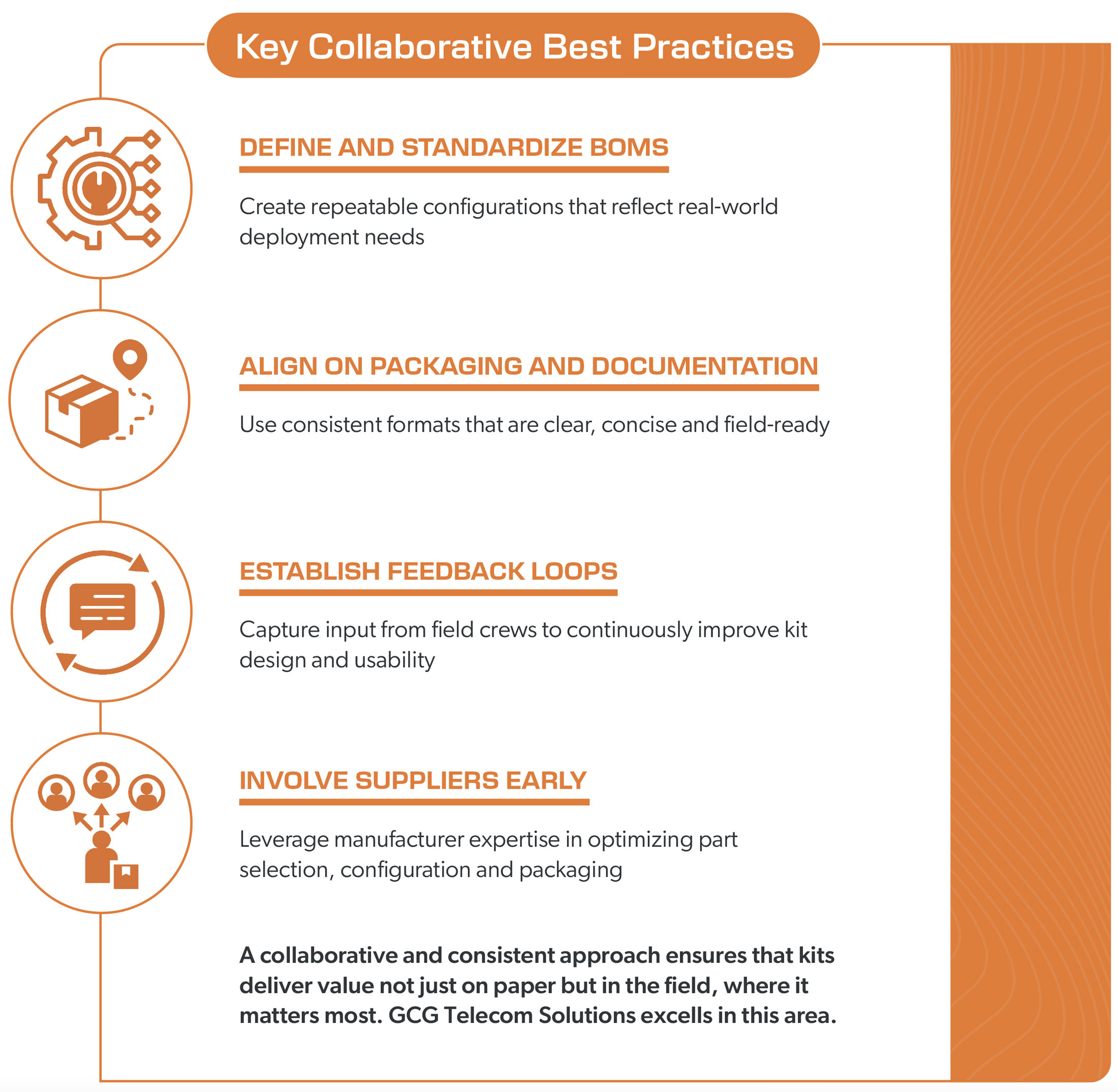

Collaboration is Key to Success

The success of any kitting and pre-assembly program depends on tight coordination between multiple stakeholders. From engineering to procurement to field ops, alignment is essential to ensure kits are not only technically sound but also practical and usable in the field.

Scaling Smarter with Pre-Assembly

As demand for network infrastructure accelerates and deployment complexity grows, pre-configured solutions will play an increasingly vital role in deployment strategy. Kitting and assembly services enable faster rollouts, reduce risk and help teams manage with fewer labor resources.

Organizations that invest in pre-assembly today will be better equipped to meet aggressive buildout goals tomorrow with higher quality, lower costs and fewer surprises along the way.